March / April 2020

Maintaining WIDGEON

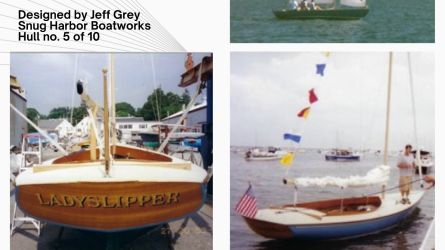

Owner Joe Murray brought WIDGEON back from the brink after purchasing her in 1980. The 48′6″ Dawn power cruiser has been a challenging but very rewarding part of his life. For the past several years, he has enjoyed the ease of keeping up with, rather than catching up on, her maintenance.

Maryland’s coast is lined with complex, sharp pockets of Chesapeake water that make up its magnetically beautiful estuaries. Thickly settled neighborhoods attest to the magnetism, and docks jut out from nearly every waterfront property there. One house in a quiet cove in Edgewater has a family jewel perched at the end of its dock. WIDGEON, a 48' 6" Dawn power cruiser, is turning 90 this year.

The first thing that owner Joseph F. Murray will tell you about this boat is that five generations of his family have enjoyed Dawns. His approach to caring for the large motoryacht, though he admits freely to the impetus of nostalgia, has been practical, thorough, and focused after purchasing her back in 1980. When he found her, she had been painted white from cabintop to waterline, and it was taking the work of three bilge pumps to keep her afloat.

Romanticism made him buy the boat: He stepped aboard and was instantly transported to his grandfather’s 45' 6" Dawn, THREE SEAS, because the layouts were nearly identical. It had been a long time. His grandfather bought that boat in 1942 and sold it in 1958 due to declining health. WIDGEON brought him back to that time…chilling a bottle of Coke on the block ice in the icebox, and catching flak for it from Grandpa after it left an indentation…being on vacation in Port Jefferson, snug in a bunk and peeking out of a porthole when he was supposed to be asleep…polishing 4'-long bronze shift levers and coiling docklines. Looking around at the state of WIDGEON, he knew it would be a lot of work to reach his goal of restoring her as faithfully as possible to her original condition, and he’d have to do most of it himself.

But here we are, 40 years and three major refits later, and Joe is still polishing, coiling, and reveling.

To read the rest of this article:

Click the button below to log into your Digital Issue Access account.

No digital access? Subscribe or upgrade to a WoodenBoat Digital Subscription and finish reading this article as well as every article we have published for the past 50-years.

ACCESS TO EXPERIENCE

2-for-1 Print & Digital Subscription Offer

For this holiday season, WoodenBoat is offering our best buy one, get one deal ever. Subscribe with a print & digital subscription for $42.95, and we’ll give you a FREE GIFT SUBSCRIPTION to share with someone special.

1 YEAR SUBSCRIPTION (6 ISSUES)

PLUS ACCESS TO MORE THAN 300 DIGITAL BACK ISSUES

PRINT+DIGITAL $42.95

Subscribe

To read articles from previous issues, you can purchase the issue at The WoodenBoat Store link below.

Purchase this issue from

Purchase this issue from